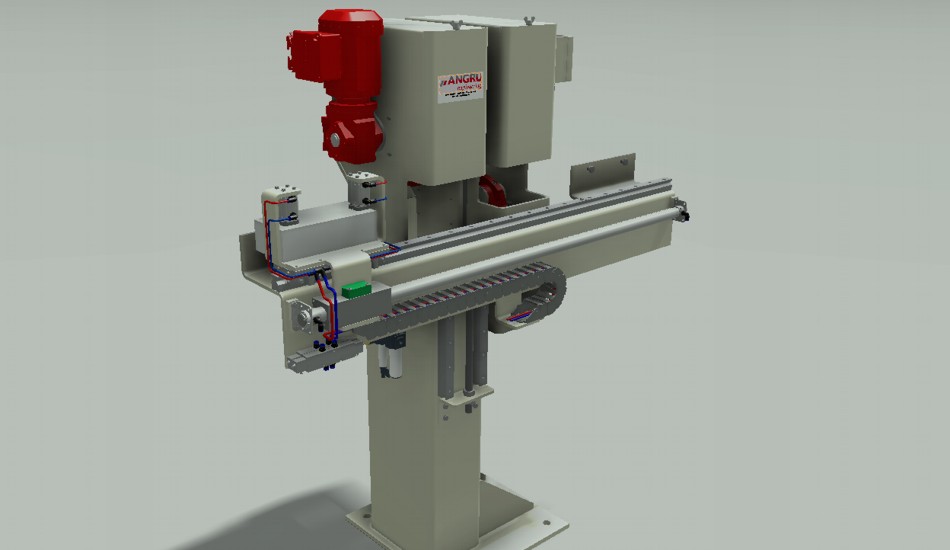

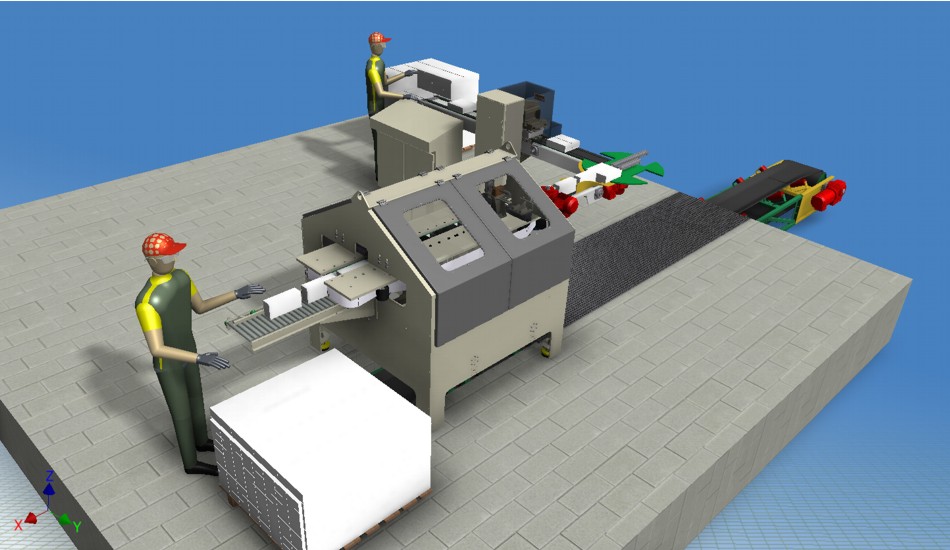

ANGRU core drill bit

View the embedded image gallery online at:

https://angru-engineering.de/en/products/processing-machines#sigProId8ab086850c

Projectinformations

-

Products

ANGRU core drill bit

-

Description

The core drill bit is used for core drillings in cellular concrete (aac) blocks which are used as corner connectors in wall constructions. Several layers of blocks build a round cavity which is then reinforced and filled with concrete.

Technical details:

- Size: W x L x H: 200-400 x 600 x 250 mm

- Cavity diameter: Ø100 - 200 mm (according to demand)

- Installed power: 3.37 kW

- Capacity: approx. 60 – 90 blocks/h (dependent on material density)

https://angru-engineering.de/en/products/processing-machines#sigProId8ab086850c

Projectinformations

- Products ANGRU core drill bit

-

Description

The core drill bit is used for core drillings in cellular concrete (aac) blocks which are used as corner connectors in wall constructions. Several layers of blocks build a round cavity which is then reinforced and filled with concrete.

Technical details:

- Size: W x L x H: 200-400 x 600 x 250 mm

- Cavity diameter: Ø100 - 200 mm (according to demand)

- Installed power: 3.37 kW

- Capacity: approx. 60 – 90 blocks/h (dependent on material density)